Product Introduction

Our company adopts internationally advanced production equipment and processes to provide 2-component evaporation boats (made of TIB2 and BN), which greatly improves the stability of the product. Our products have world-class excellent evaporation performance and stable quality, which can meet the production of various metallized films, paper, textiles and other materials. They are widely used in vacuum evaporation film materials, capacitor metallization vacuum coating, paper aluminum plating, hot stamping coating, anti-counterfeiting logo aluminum plating and other industries.

Our advantages

All sizes can be customized

Products without pinholes

Price competitiveness

Lower power consumption

Shorter preheating time

Better aluminum liquid spreading ability

Less sputtering and boat bending problems

Longer service life

Ultra-fast logistics advantages

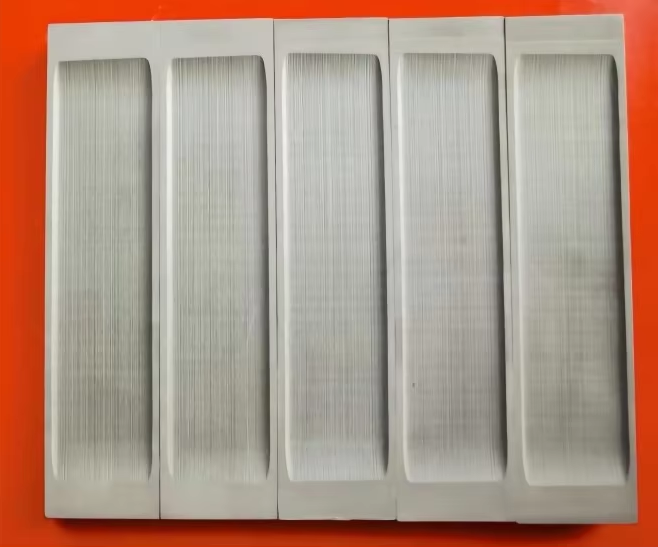

Evaporation boat features and advantages

Our boats are resistant to high temperature, thermal shock and corrosion, and have excellent wettability in the presence of aluminum melt

The use of high-purity and high-quality raw materials ensures that the materials have good chemical properties.

The internationally advanced vacuum hot pressing sintering method is adopted to ensure the excellent physical properties of the product.

The sintering process adopts a two-way pressurization method to ensure the consistency of the product volume density.

Exclusive process formula, optimized composition structure, enhanced thermal shock resistance and flexural strength of the evaporation boat, improved aluminum liquid spreading ability and evaporation efficiency, and enhanced aluminum liquid corrosion resistance.

Conventional size:

130*30*10 150*30*10 120*24*10 125*40*10 130*35*10

130*38*9.5 125*24*10 110*24*8 110*35*10 125*38*10

Evaporation boat performance

Characteristics | Unit | Data |

Chemical composition | BN+TiB2 | |

Density | g/cm3 | >3.02 |

Modulus of Elasticity | Gpa | 60-70 |

Flexural Stength | Mpa | >150 |

CTE | (10-6/K) | 5-7 |

Thermal Conductivity at 20℃ | W/mk | 100/40 |

Max-Temperature of Use | Oxidizing | 900℃ |

Vacuum | 1850℃ | |

Inert | 2000℃ | |

RT Resisitivity | 300-2000 | |

售前咨询专员

售前咨询专员